Maintenance-free whirlwinds

Kaeser KC centrifugal separators remove condensate at the compressor's compressed air discharge point. They're a must for faultless and energy-efficient functioning of downstream dryers and filters. KC centrifugal separators are equipped with the economical and extremely reliable ECO-DRAIN 31 condensate drain – naturally, with test button and alarm contact included.

- Separation rates up to 99 % in the flow rate range of 0.9 to 14.2 m³/min

- designed for working pressures up to 16 bar

- with ECO-DRAIN 31 electronic condensate drain

- with optional wall mounts

Models with flow rates up to 88.5 m³/min, special product variants available in silicon-free design, for working pressure of 45 bar.

Your advantages

- Comprehensive efficiency:

Kaeser has optimised the air flow in the KC centrifugal separator using the most advanced flow simulations and measured it as per ISO 12500-4. The results: a swirl insert with an excellent separation rate of up to 99 % – stable over a broad output range and with pressure loss of less than 0.1 bar. - Durable and value-retaining

With a seawater-resistant aluminium enclosure and an additional passivation coating, our centrifugal separators are built to keep on running. The compressed air connections on the enclosure are thus always a perfect fit for our rotary screw compressors. - Maintenance-free:

Kaeser KC centrifugal separators are maintenance-free. Furthermore, the ECO-DRAIN condensate drain is equipped with a service module for highly reliable maintenance.

Product details

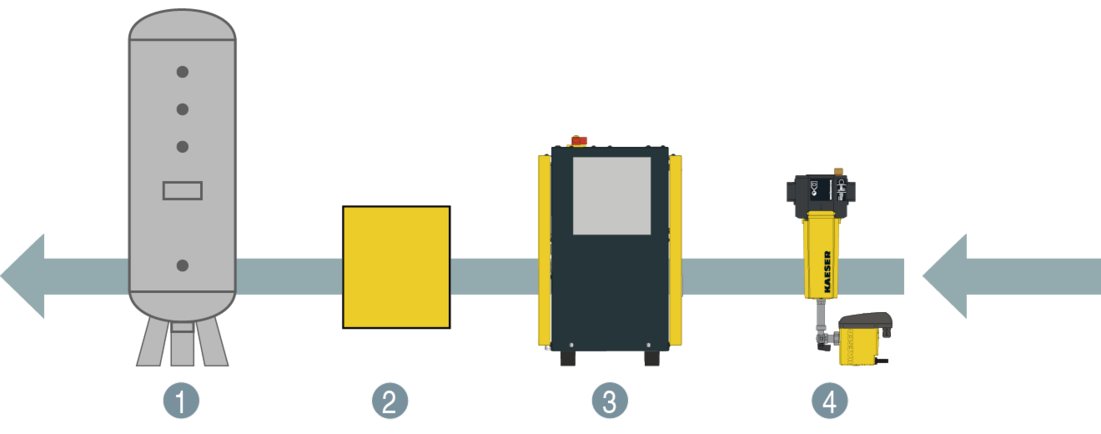

- Air receiver

- Optional filtration

- Refrigeration dryer

- Centrifugal separator