i.HOC – Outstandingly efficient compressed air drying

The patented i.HOC rotary dryer from Kaeser uses up to 100 % of compressor heat! Thanks to full-flow regeneration, it delivers reliable pressure dew points up to an ambient temperature of 45 °C – completely without electrical heating or additional cooling of the regeneration air!

- Installed in air-cooled or water-cooled units

- Unit rated power from 37 kW to 355 kW

- Unit flow rates from 4.2 m³/min to 51 m³/min

- Integrated SIGMA CONTROL 2 compressor controller (SFC model versions)

Your advantages

- Sub-zero pressure dew points even in high ambient temperatures:

Thanks to its extraordinary regeneration potential, the i.HOC delivers below-zero pressure dew points even with high cooling medium temperatures. - Pressure dew point stability even with variable flow rates:

The pressure dew point remains stable even with low compressor load – no partial-load compensation required. - Effective drying AND heat recovery:

i.HOC uses the heat exchangers of the second compression stage, which have been optimised for heat recovery, as regeneration air coolers.

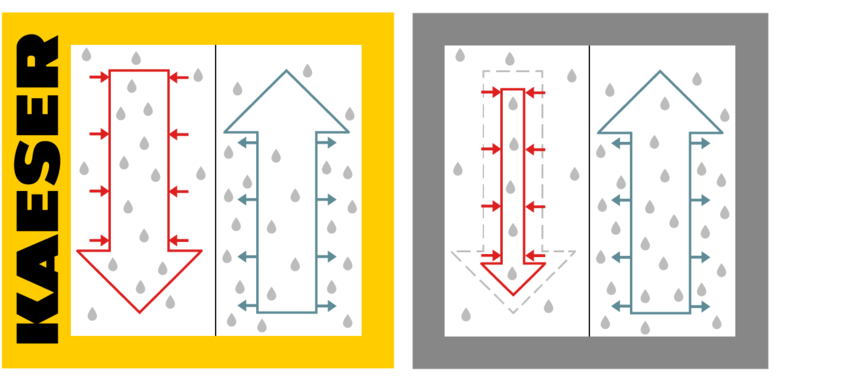

Benefits of full-flow regeneration

| □ Full-flow regeneration | □ Partial-flow regeneration |

| ↓ Regeneration area: Hot air removes moisture from the desiccant. | |

| ↑ Drying area: Moisture is drawn into the desiccant from the cold air. | |

The i.HOC (Integrated Heat of Compression Dryer) uses 100 % of the heat of compression from the second compressor stage for drying purposes (full-flow regeneration). This heat, which is produced in any case, is therefore effectively available at zero cost.

- No additional energy input for the drying process

- Higher regeneration potential than dryers with partial-flow regeneration

- Full performance, even at low compressor load

The advantages of full-flow regeneration become particularly evident at increased cooling medium temperatures. KAESER rotation dryers achieve outstanding drying results, even without additional electrical heating of the regeneration air.

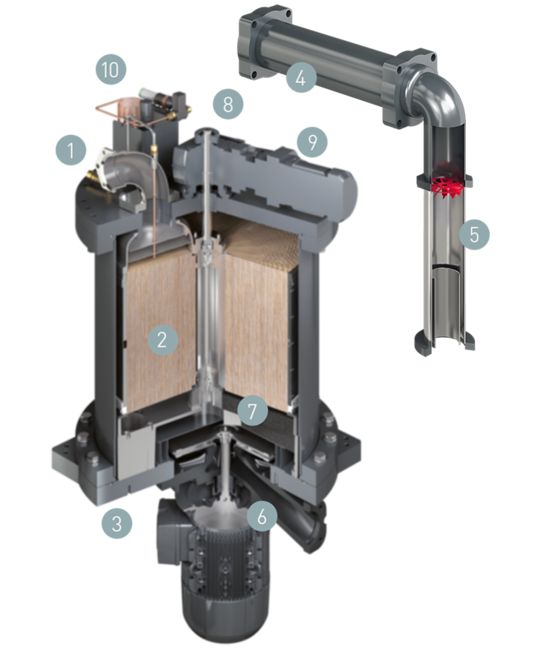

The oil-free compression rotary screw compressors with integrated i.HOC or refrigeration dryer in detail

Energy-saving drying

Integrated design, together with the generously-dimensioned aluminium block heat exchanger, helps ensure minimal pressure loss of less than 0.1 bar. The energy-saving scroll refrigerant compressor helps to achieve additional compressed air energy savings.

Excellent accessibility

All refrigeration dryer components are perfectly accessible via the service door on the front of the unit. Dryer service and maintenance work is therefore a breeze.

- Regeneration air inlet

- Regeneration air outlet

- Condensate separation

- Radial fan inlet

- i.HOC outlet

- Regeneration air inlet

- Drum (silica gel desiccant)

- Regeneration air outlet

- Heat exchanger stage 2

- External condensate separator

- Radial fan

- Demister (droplet separator)

- Rotation dryer outlet

- Drum motor

- Pressure dew point sensor (optional)