Analysis methods for maximum efficiency

Whether it’s optimisation of an existing system or tailored planning of a new one: KAESER AIR SERVICE provides excellent advice and analytical expertise. Using analytical methods developed in-house in compliance with ISO 11011 and a trained instinct for the needs of a diverse range of industries, our experienced service technicians and engineers create future-proof solutions which not only save money, but also preserve the environment.

Your benefits

- Excellent advice and analysis

- Future-proof system optimisation

- Analysis methods in accordance with ISO 11011

We design your compressed air future in four steps

Step 1: Understanding your needs

No two businesses are the same.

For this reason, our compressed air experts firstly create a precise demand profile for each field of application.

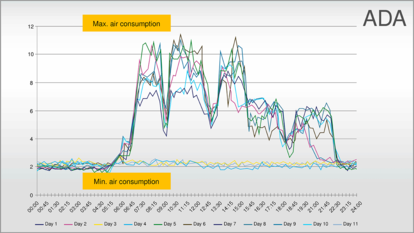

Step 2: Air Demand Analysis – ADA

Next, a computer-aided Air Demand Analysis (ADA) is conducted of the actual compressed air demand on the system. To ensure that this analysis is as precise as possible, it is performed in all areas of the operation and at different utilisation rates.

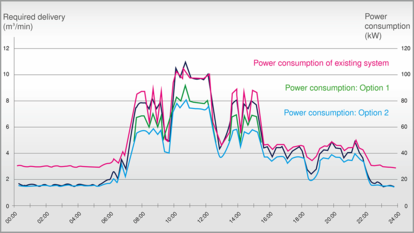

Step 3: KAESER Energy Saving System KESS

Using the KAESER Energy Saving System, KESS, the performance characteristics of the station are forecast and promising energy-saving models compared.

Step 4: The individual compressed air station

The end result is a tailored solution which delivers maximum efficiency.