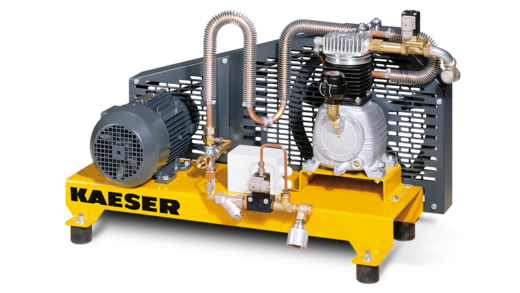

Your ticket to high-pressure performance

N-series boosters augment your existing system pressure in specific locations, elevating it up to 45 bar. Kaeser offers an extensive range of high-performance booster reciprocating compressors that work in perfect harmony with Kaeser rotary screw compressors and SIGMA PET AIR stations.

The N-series boosters are available with one or two cylinders and operate within the following performance parameters:

- Initial pressure up to 13 bar – discharge pressure up to 45 bar

- Flow rate: 0.27 – 5.49 m³/min

Compared to designing the entire compressed air supply system for higher pressure, the use of boosters is significantly more cost-effective for all applications that require process air with a higher degree of compression than the normal control air and supply air at specific locations. PET bottle production is an excellent example of such applications.

Your advantages

- Continuous high-pressure operation:

Innovative features such as oil pressure lubrication and intensified cylinder cooling ensure both long service life and low maintenance requirements as well as continuous system-compatible maximum pressure of 45 bar. - Exceptionally low oil requirement:

The high quality cylinders are plateau-honed and feature an extra layer of wear protection. These details ensure low oil consumption over the entire service life. - For especially cool compressed air:

The compressed air aftercoolers on the three-cylinder boosters are equipped with separate fans, which ensure low compressed air discharge temperatures. The boosters can be additionally equipped with water-cooled aftercoolers to attain even lower temperatures.

Energy cost savings

High-quality premium efficiency electric motors deliver unparalleled efficiency for remarkably low power consumption. Their low operating temperature provides an added advantage.

Product details

For lower demand

For medium to large demand

- Rotary screw compressor

- Air receivers

- Booster

- "High-pressure" air receiver

- "High-pressure" refrigeration dryer

- Pneumatic tools

- Low pressure network up to 13 bar

- Prefilter

- High-pressure microfilter

- Compressed air network at 45 bar