Cost-effective solutions for optimal compressed air quality

KAESER FILTER products are the key components for producing compressed air to all purity classes as per ISO 8573-1. All with exceptionally low differential pressure. Moreover, their service-friendly design not only allows simple, error-free opening and closing of the filter housing, but also enables quick and clean element changes.

- Flow rate: 0.60 to 32.0 m³/min

- Max. working pressure 16 bar

- Max. operating temperature 66 °C

Your advantages

- Standard-compliant purity:

The KAESER FILTER range uses modern deep-pleated filter media to remove particles and aerosols. A highly effective carbon fibre mat traps oil vapours. The outstanding performance data of KAESER FILTERS were calculated according to ISO 12500 and validated by Lloyd's Register, the independent certification organisation. - Low pressure loss – high savings:

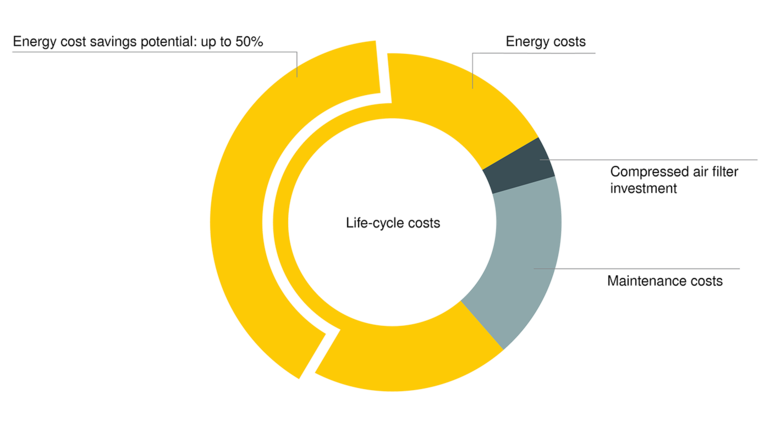

KAESER FILTER products feature generously dimensioned housings and filter surfaces, innovative flow dynamics and high-performance filter media. They feature up to 50% lower pressure loss than other available filters – a value which remains virtually constant over the entire service life of the filter element. This means lower costs and CO2 emissions as well as reduced load on upstream compressors. - Service-friendly design – straightforward handling

KAESER FILTER products feature a corrosion-resistant aluminium housing and a stable filter element. The practical bayonet lock ensures automatic positioning of the housing and element seals, which prevents the filter housing from being sealed unless a filter element has been inserted. A locking screw prevents unintentional opening of the housing when under pressure and also provides housing venting.

Product details

| Degree of filtration | KB Coalescence filter

Basic | KE Coalescence filter

Extra | KD Particulate filter

Dust | KA Activated carbon filter

Adsorption | KBE Extra Combination | KEA Carbon Combination |

|---|---|---|---|---|---|---|

| Initial differential pressure with saturation | < 140 mbar | < 200 mbar | < 30 mbar

(New, dry) | < 35 mbar

(New, dry) | < 200 mbar | < 240 mbar |

| Aerosol content at inlet | 10 mg/m³ | 10 mg/m³ | – | – | 10 mg/m³ | 10 mg/m³ |

| Residual aerosol content at outlet according to ISO 12500-1 | < 0.01 mg/m³ | < 0.01 mg/m³ | – | – | < 0.01 mg/m³ | 0.003 mg/m³

(Total oil content) |

| Filter medium | Deep-pleated with support structure and polyester drainage fibre | Deep-pleated with supporting structure | High-efficiency carbon fleece | – | – | |

| Application | Filtration of solid and liquid aerosols and solid particles | Same application as KB, but for higher compressed air quality;

alternatively: Micro-particle filter to KD degree of filtration | Exclusively for the filtration of solid particles | Exclusively for the removal of oil vapours | Combination of KB and KE; application as KE, but for higher assurance of compressed air quality | Combination of KE and KA, filtration of aerosols, solid matter particles and oil vapours |

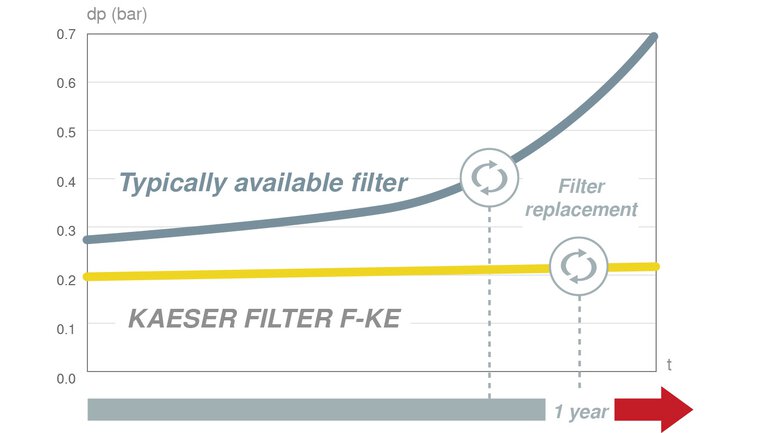

Pressure loss is the most significant factor affecting the efficiency of compressed air filters. KAESER FILTER products feature generously dimensioned housings and filter surfaces, innovative flow dynamics and high-performance filter media. These features result in up to 50 % lower pressure loss in comparison to other typically available filters. Moreover, this outstanding filtration performance remains virtually constant throughout their entire service life. This reduces the load on upstream compressors, thereby creating the potential for significant reductions in costs and CO2 emissions.

Life-cycle cost savings

Want to find out more about how Kaeser is cutting life-cycle costs?

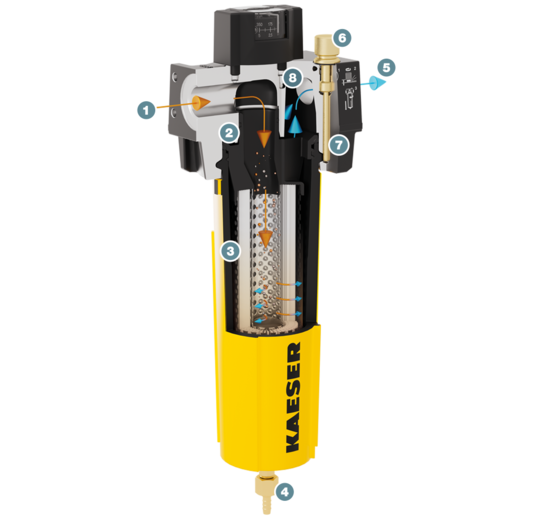

- Compressed air inlet

- Element head with housing and element sealing

- Filter element

- Condensate outlet (here with automatic condensate drain)

- Compressed air outlet

- Locking screw

- Bayonet lock with limit stop

- Vent hole

KAESER FILTER products demonstrate a lower pressure drop right from the outset compared to other typically available filters on the market. Moreover, the pressure drop remains low for much longer thanks to the high particulate retention capacity.

The result: low operating costs over the long term. The annual maintenance of particulate and coalescence filters mitigates age-related risks and ensures maximum compressed air purity.