Compressed air stations with integrated refrigeration dryer and air receiver

Compressed air stations (*) from the SXC series have been especially designed by KAESER for trades and crafts applications. Featuring a footprint of just 0.62 m², they combine all of the components required for a compressed air supply beneath a single, durable polyethylene enclosure: a rotary screw compressor with the SIGMA PROFILE, a refrigeration dryer and an air receiver.

Compressed air stations from the SXC series are available with the following performance specifications:

- Pressure: 8, 11 or 15 bar

- Flow rate range: 0.26 – 0.80 m³/min

Your benefits

- Plug and play:

Our all-in-one compressed air systems require minimal effort when it comes to piping and installation. Simply connect the station to a power supply and your compressed air network and that’s it – you’re ready to go! - Protected from corrosion damage:

Thanks to the integrated refrigeration dryer, SXC systems deliver high-quality compressed air that protects your tools and equipment from corrosion damage. - Simple maintenance:

All maintenance points are easily accessible by lifting off the lightweight, removable enclosure constructed from rotomoulded polyethylene. The electronic condensate drain can be inspected via a grille. Maintenance is simple and effective.

* This dryer series contains fluorinated greenhouse gases. All models contain refrigerant R-513A (GWP 631).

Profitable thanks to low life-cycle costs

Our comprehensive approach to optimal profitability: Optimal efficiency, easiest operation, service-friendliness and a global service and consulting network with fast response times.

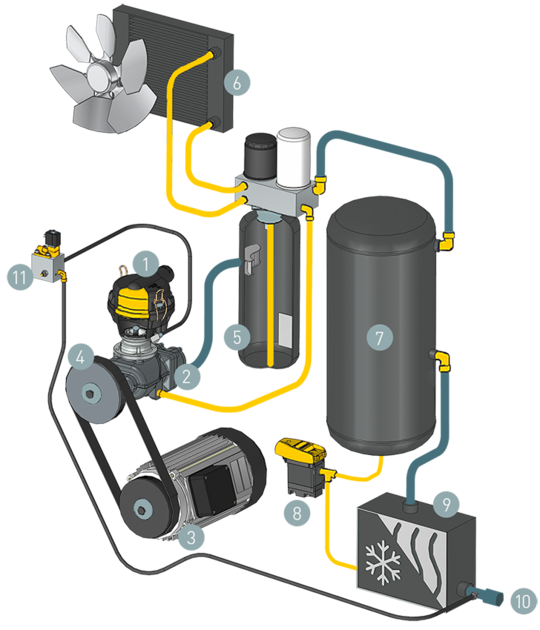

SXC compressed air package in detail

Complete unit

- Ready-to-run

- Fully automatic

- Super silenced

- Vibration-damped

- Double-skinned rotational moulded polyethylene enclosure

- Optimal accessibility of all service points after cover removal

Sound insulation

- Sound enclosure

- Anti-vibration mounts

- Dual anti-vibration mounts

Electric motor

- Energy-saving motor (IE3)

- Quality German manufacture

- IP 54

- Insulation class F for greater power reserve

Rotary screw airend

SIGMA PROFILE rotors require approximately 10 to 20 percent less energy than conventional rotors of the same air delivery capacity.

V-belt drive

- Maintenance-free belt

- No re-tensioning necessary

Fluid and air flow

- Honeycombed dry air filter

- Inlet with check valve

- Pneumatic venting valve

- Cooling fluid tank with separately installed separator cartridge

- Pressure relief valve

- Minimum pressure/check valve

- Micro-filter in the cooling fluid circuit

Cooling

- Air-cooled

- Aluminium cooler for cooling fluid with separate fan motor

- Second fan on drive motor shaft

- Automatic warm run control (only active at very low loads)

Receiver

- Internally coated

- Electronically controlled condensate drain

SIGMA CONTROL 2

- Traffic-light LEDs for at-a-glance operational status

- Easy-to-read display

- 30 selectable languages

- Soft-touch icon buttons

- Fully-automatic monitoring and control

- Interfaces: Ethernet

- SD card slot for data logging and updates

- RFID reader

- Web server

Electrical components

- Control cabinet to IP 54

- Automatic star-delta contactor combination (above 3 kW)

- Overcurrent trip

- Control transformer

Refrigeration dryers

- Control cabinet to IP 54

- Automatic star-delta contactor combination (above 3 kW)

- Overcurrent trip

- Control transformer

- Contains fluorinated greenhouse gas R-513A

- Air filter

- Airend

- Drive motor

- Automatic belt tensioning

- Fluid separator tank

- Cooler

- Air receiver

- ECO DRAIN condensate drain

- Refrigeration dryer

- Compressed air outlet

- Control valve