Diesel-driven compressors up to 48.1 m³/min (1700 cfm)

Compact, powerful and versatile – Performance is more than a promise with diesel-driven MOBILAIR portable compressors from KAESER. As true powerhouses of the MOBILAIR range, these oil-injected portable compressors combine exceptional performance with compact design. The necessary power is provided by EU emission level V engines to ensure dependable and environmentally-friendly operation.

These versatile machines can be perfectly adapted to meet the needs of the specific application thanks to a wide range of optional treatment components that always deliver the required compressed air quality. Furthermore, the generously-sized fuel tank ensures impressive construction site staying power. When full, the fuel tank has sufficient capacity to last an entire work shift.

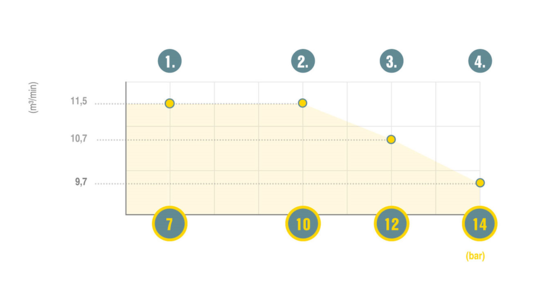

These diesel-driven compressors also feature dynamic ‘pV control’ to provide incredible flexibility, meaning that one and the same system can deliver pressures between 6 and 14 bar. This makes them ideal for cable blowing and drilling, for blasting work and concrete processing, as well as for providing backup air in opencast mining and industrial applications.

Performance data:

- Flow rate up to 48.1 m³/min (1700 cfm)

- Working pressure up to 14 bar (200 psi)

Available models:

| Model | Available for which market | Generator option |

|---|---|---|

| M118 pV | EPA-markets | no |

| M125 pV | CE- and EPA-markets | yes |

| M135 pV | non-regulated markets | no |

| M171 | CE- and EPA-markets | no |

| M210 | non-regulated markets | no |

| M235 | non-regulated markets | no |

| M255 pV | CE- and EPA-markets | no |

| M450 pV | non-regulated markets | no |

Your benefits

-

Compressed air with integrated electric power supply:

The generator function eliminates the need for a separate power supply to operate your pneumatic and electrical tools or lighting. -

Clean and oil-free compressed air:

Depending on the specific application, MOBILAIR portable compressors can also be equipped with microfilter combinations for technically oil-free compressed air, such as required for blasting applications as per German ZTV-ING regulations. This option delivers compressed air with an oil aerosol content of < 0.01 mg/m³, as per the requirements of ISO 8573-1. -

pV control:

The advantages of ‘pV control’ truly shine when it comes to cable blowing: Initially, large volumes of air at lower pressure are used to accelerate the cable. Once in progress, more pressure and lower delivery volume are then used for long sections.

Always up-to-date with TELEMATICS

With the Telematics 36 @ MOBILAIR (PDF, 1.38 MB) option, Industrie 4.0 comes to the construction site. Following approval of the data usage contract, KAESER equips every M250E / M255E – ex-works and at no extra cost – with a modem and connects it to the Telematics portal.

The best part: KAESER pays the portal fees for 36 months. You can therefore view operating data, current messages and system location online. Through the anonymous evaluation of machine data by KAESER, you help to make MOBILAIR compressors even better.

Our compressor powerhouses in detail

- Breaker application

- Blasting application

- Cable blowing

- Drilling application

Maximum pressure (p) can be adjusted in steps of 0.1 bar between 6 and 14 bar. With pV Control, this directly influences the maximum possible flow rate (V), thereby providing even greater flexibility with regards to both pressure and flow rate. This feature is particularly beneficial when working with longer hose lines.

The image shows pV Control functionality, using the MOBILAIR M125 as an example.

KAESER placed special emphasis on user-friendliness when designing the operating concept for their portable powerhouses. This focus resulted in a simple and intuitive user interface featuring a single rotary switch for start-stop operation. Pressure can be adjusted just as easily on the touchscreen display of the SIGMA CONTROL MOBIL 2 compressor controller – even when wearing unwieldy work gloves. The pV control can therefore be perfectly tailored for every application, and the easy-to-read touchscreen display provides a clear overview of all operating data. Using state-of-the-art electronic engine management, the compressor controller ensures optimised compressed air availability, fuel efficiency and exhaust air minimisation. The operating unit is protected from damage by a durable metal cover flap.