From frost protection to high-tech applications

Desiccant dryers from the i.DC series can lower the pressure dew point of the compressed air to -70°C. They combine reliable system design, impressive energy efficiency and exceptionally low maintenance costs. Enjoy dependable frost protection for your control valves and lines while producing dry compressed air for sensitive processes with minimal total costs.

- PDP down to -70 °C

- Flow rate 1.60 to 155.50 m³/min

- Energy-saving ECO CONTROL 3 for comprehensive system monitoring

- Can optionally be coupled to an ACT activated carbon adsorber – for technically oil-free compressed air to meet the strictest requirements

Your benefits

- Reliable and compact:

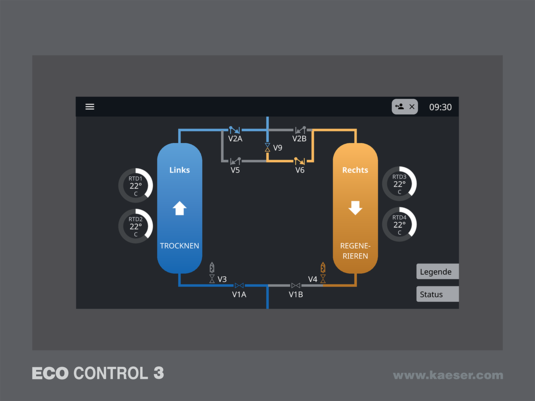

High-quality components, water-resistant high-performance desiccant and generous fill levels. All models are installed on a rugged, space-saving frame. - ECO CONTROL 3 – efficient and network-capable:

The network-capable controller with 7” touch display provides comprehensive system monitoring with an extensive reporting system, graphic display of process parameters and a P&I diagram with integrated real-time data. The standard-equipped Dew point trend recognition control ensures significant energy savings during partial load operation. With the optional pressure dew point sensor, the pressure dew point can be displayed and also used as a control variable, alternatively to trend recognition. - Low-maintenance design:

Thanks to resource-friendly operation with particularly long cycle times, high-quality components such as the valves, and generous desiccant fill levels, we recommend a complete overhaul only every 5 years. This is more cost-efficient, since the overhaul procedure is quick and simple – and after all, time is money.

Product details

Available in sizes from i.DC 126 upwards, DC dryers are equipped with an ACT activated-carbon adsorber that is precisely matched to meet dryer capacity. This enables production of oil-free compressed air that meets the highest quality standards (ISO 8573-1 Class 1 residual oil content). The frame construction (up to i.DC 140) makes it easy to connect the ACT activated carbon adsorber.

KAESER ensures uncompromising efficiency even with the standard version of the i.DC series. The ECO CONTROL 3 controller and trend recognition dew point control ensure maximum energy savings during partial load operation. Generous dimensioning of the heatless regenerative desiccant dryer (e.g. 10-minute cycle for PDP of -40°C) and the consistent use of high-quality components (e.g. durable valve technology and long-lasting premium desiccant) guarantee efficient operation with minimal maintenance requirement (e.g. inspection every 5 years).

Your advantage: Minimal total costs, maximum savings.

Dependable drying

The centrepiece of the optimised i.DC series is the new ECO CONTROL 3 controller. Clearly structured menu guidance and a 7” touch display ensure optimal control over the entire drying process. For connection to a master controller or integration into the KAESER SIGMA NETWORK, a Modbus TCP (Ethernet) interface is also fitted.

Intelligent controller

The ECO CONTROL 3 provides comprehensive, advanced system monitoring, thanks to an extensive reporting system with event memory, detailed maintenance management, graphic display of the time curve for all temperatures and the pressure dew point (optional), as well as a P&I diagram with integrated real-time data.

Efficiency thanks to Dew point control

Even the basic version of the i.DC series is equipped with the durable and maintenance-free Dew point trend recognition control, providing significant energy-saving potential – particularly in partial load operation. If desired, a high-quality pressure dew point sensor can also be integrated. This allows the pressure dew point to be displayed, transmitted, and also used as a control variable, alternatively to trend recognition. A practical advantage of this is that even if the sensor does not deliver a signal, for example due to calibration, load-dependent control remains possible.