Identified! – Costs incurred and savings opportunities

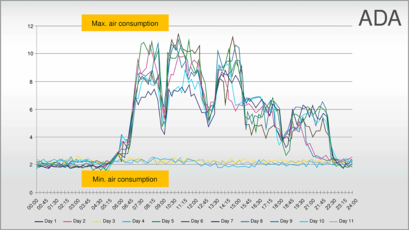

Using our air demand analysis (ADA), we generate precise consumption profiles of your system, allowing us to determine your actual air demand – throughout all operating sectors and at different loads.

- We highlight weaknesses in your existing system.

- We identify poorly dimensioned installations.

- We lay the groundwork for the next step toward the optimal compressed air station by calculating the energy-saving potential.

We take the widest range of conditions into account – regardless of whether you are looking to install a new system or simply wish to test the efficiency of your existing system.

Measurement equipment

The latest technology allows precise, computer-aided evaluations.

Power consumption

How much energy does your system actually draw from the grid?

Air demand analysis in detail

We install the measuring device at your location – on a lease basis for ten days.

An optocoupler ensures trouble-free data transfer to the ADA data-logger, which records compressor load/idle information.

The measuring system are suitable for all compressors, even frequency regulated compressors.

Compressed air audits using modern data loggers highlight the efficiency of a compressed air system with minimum effort because direct access to the cable network is unnecessary.

Optional SIGMA AIR CONTROL visualisation, in combination with the SIGMA AIR MANAGER master controller, allows the continuous measurement of the load/idle performance, duty cycle, and power consumption of every compressor.

All compressed air information can be viewed via a web browser on a standard PC and exported for operational compressed air controlling. These data can also be used to perform detailed compressed air audits.