Powerful all-rounders for your construction site

The MOBILAIR portable compressors in this series are exceptionally versatile. Optionally available with synchronous generators and/or compressed air treatment components, they are also offered in a variety of maximum pressure variants, thereby ensuring that the perfect model is always available for every application.

What's more, transporting these powerful all-rounders is a simple and convenient matter. KAESER portable compressors are equipped with lifting eyes as standard; they can also be specified as stationary versions equipped with skids or machine feet, making them the perfect choice for any operating location.

MOBILAIR portable compressors can be used wherever the key requirements are efficiency and durability. These powerful all-rounders excel when working on blasting applications and crash barrier construction. The optional generator transforms these machines into a portable power plant for the whole construction site.

Performance data:

- Flow rate up to 10.6 m³/min (375 cfm)

- Gauge working pressure up to 14 bar (200 psi)

Available models:

| Model | Available for which market | Generator option |

|---|---|---|

| M70 | non-regulated markets | no |

| M81 pV | CE- and EPA-markets | yes |

| M100 | non-regulated markets | yes |

Your benefits:

- Compressed air and electrical power

The generator function eliminates the need for a separate power supply to operate your pneumatic and electrical tools or lighting. - Easy-to-read display

Operating pressure can be conveniently adjusted via the SIGMA CONTROL MOBIL 2's touchscreen, even when wearing unwieldy work gloves. Additionally it provides a clear overview of all operating data. - Reliability with excellent value retention

MOBILAIR portable compressors are well equipped for the demands of heavy-duty and continuous operation in construction site environments. They perform reliably and safely even under harsh climatic conditions.

Environmentally friendly and low-emissions

The M82 portable compressor is designed to provide clean air – not just for low emission zones – certified to EU Directive 2016/1628, Stage V. Furthermore, with a diesel particulate filter fitted as standard, the M82 meets the stringent requirements of the Swiss Clean Air Act.

Maximum compressed air availability

The M82 and M100 are available with the option of either an 8.5 or a 13 kVA generator. Ensuring perfect interplay with the engine management system, the SIGMA CONTROL SMART compressor controller delivers maximum compressed air availability relative to power demand.

Our versatile portable compressors in detail

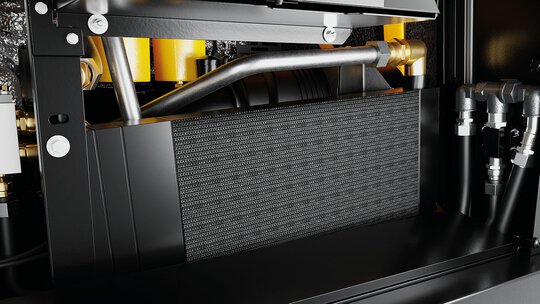

The compressed air is cooled to 7°C above ambient temperature. The compressed air cooler is installed at an angle, allowing accumulated condensate to drain away easily, whilst the hot exhaust gases from the engine are used to aid condensate evaporation. This prevents the cooler from freezing up as a result of accumulating condensate. Additional air treatment components may need to be installed downstream from the aftercooler and centrifugal separator (e.g. filter combinations for concrete cleaning as per ZTV-ING) in order to achieve compressed air of a specified quality class.

Oil-lubricating or oil-free? – Depending on the application, MOBILAIR machines can be optionally equipped with a tool lubricator to provide oiled compressed air for lubricating air tools, or with a microfilter combination for blasting work requiring technically oil-free compressed air.

Dry compressed air – The plate-type heat exchanger reheats the cooled compressed air using heat from the compressor cooling fluid. This prevents condensation from forming outside the unit when the compressed air cools. The compressed air temperature can easily be adjusted as required from the exterior of the machine.