Dependable performance – up to +45°C ambient temperature

In the absence of a cooling-water infrastructure, air-cooled, oil-free compression rotary screw compressors ensure exceptional compressed air supply dependability – even in ambient temperatures up to +45°C. There’s also plenty of power: thanks to innovative and intelligent system design, we can provide air-cooled, oil-free compression rotary screw compressors up to 355 kW.

- Flow rate from 4.2 to 51 m³/min

- Pressure from 4 to 11 bar

Your benefits

- Heat-use made simple:

Thanks to radial fans with high residual thrust, the heated cooling air can normally be used straight away for space heating without need of auxiliary fans. - Energy-efficient in every detail:

In standby mode, the temperature-controlled Kaeser standstill fan reliably conveys residual heat away – meaning the main fan can be switched off! - Exceptionally maintenance-friendly:

The first and second stages of the aluminium-block heat exchanger can simply be swivelled out for cleaning purposes.

Highlights of our air-cooled CSG series

Water jacket-cooling

The effective water jacket-cooling achieves an efficiency increase of several percentage points in comparison to oil jacket-cooling. Moreover, the service life of the gear oil is increased to 18,000 operating hours.

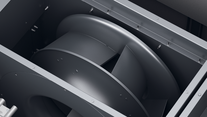

Variable cooling air flow rate

Thanks to the innovative fan system, cooling air flow is regulated as needed. This enables optimal adjustment to the corresponding load situation and cooling air temperature.

Air-cooled, oil-free compression rotary screw compressors in detail

The purchase price and service costs account for just a fraction of the total lifetime cost of a compressor. Energy accounts for the lion's share of the system’s costs. As a leading compressed air systems provider, we offer individual planning tailored to your exact needs, an energy-efficient compressed air station and reliable service. We are there to partner you throughout the entire service life of your compressed air station.

The integrated SIGMA CONTROL 2 controller coordinates compressed air generation and ensures efficient, reliable machine operation. Moreover, it guarantees perfect interaction within the integrated system as a whole. All relevant components and operating states are monitored and evaluated. A multitude of communications functions are available to the operator, including the option of connecting the machine to other control technology (SCADA).

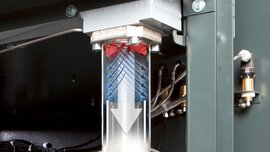

Fibre-free pulse dampers

Kaeser's new fibre-free pulse dampers keep pressure losses to an absolute minimum, help maintain consistent air quality and, unlike fibre versions, do not present a source of contamination for the compressed air.

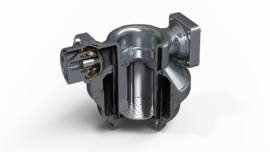

Highly efficient condensate separator

Thanks to its flow-optimised design, the newly developed condensate separator reliably separates the condensate downstream from the air coolers, with minimal pressure loss.

Bolt-down machine mounts

- Machine mounts to bolt the machine to the floor

Silencer for air inlet opening

- Damping louvres in front of heat exchangers

Cooling air filter mats

- Cooling air filter mats in the inlet area of the compressor

- Reduce soiling of heat exchanger surfaces and inlet air filters

Hot air connection

- Direct use of the hot compressed air, e.g. for heat regenerating desiccant dryer or as hot process air

- With certain models, the desired hot air temperature can be controlled in ranges.