Rugged space-savers for optimal moisture protection in all load phases

KRYOSEC compact refrigeration dryers* impress with their Made in Germany industrial quality. Offering dependable moisture protection in ambient temperatures up to +50 °C, the combination of a stainless steel heat exchanger featuring extremely low pressure loss and a low-maintenance overall design guarantees highly efficient operation. Thanks to their compact design, they can be installed directly where they are needed – whether under machine and work platforms, or even attached to a wall (TAH series).

- Reliably dry compressed air from 0.35 to 4.5 m³/min

- Working pressure up to 16 bar

- Options: ECO-DRAIN electronic condensate drain and/or electronic thermostat for pressure dew point warnings – both with floating alarm contacts

Your advantages

- Reliable moisture protection

KRYOSEC dryers use a high-quality heat exchanger system with stainless steel plates to dry the moist compressed air. Accumulating condensate is efficiently separated in all operating phases via the integrated separator and then reliably removed via the ECO-DRAIN electronic condensate drain. - Dependable performance, even in high ambient temperatures:

KRYOSEC dryers ensure reliable moisture removal, even under the most demanding of operating conditions. Performance is also enhanced by the defined cooling airflow plus the combination of a generously-dimensioned heat exchanger and refrigerant condenser surfaces. - Standard-compliant industrial quality:

KRYOSEC dryers comply fully with the safety requirements for machines in accordance with EN 60204-1. Safety features include a lockable ON/OFF switch and a power supply isolating device. High-quality manufacture and a compact design make KRYOSEC dryers ideal for use within a decentralised installation – positioned directly alongside production and processing machines that require compressed air treated to the highest purity classes.

* Dryers from this series contain the fluorinated greenhouse gas R-513A.

Product details

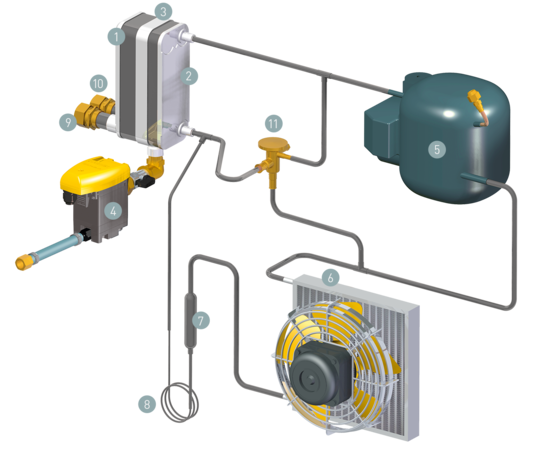

Refrigerant circuit

- Refrigerant circuit consisting of reciprocating compressor

- Fan-condenser assembly

- Filter dryer

- Capillary tubes

- Insulated air/air and air/refrigerant heat exchangers with integrated stainless steel (copper soldered) condensate separators

- Hot gas bypass controller

Condensate drainage

- ECO-DRAIN 30 electronically-controlled condensate drain with tap on the condensate inlet, incl. cold surface insulation

Electrical equipment and displays

- Mechanical dew point trend display

- Electric equipment to EN 60204-1: lockable main switch with integrated mains isolation device

Enclosure

- Powder-coated unit enclosure with removable hood and machine mounts

- Prepared for wall mounting (only TAH series)

Connections

- Design includes strain-relieved main connector cable (without plug)

- Internally wired

- Bulkhead pipe fitting for external condensate drain connection

Documentation

- Includes operating manual and CE marking (EU version)

Optional: "Pressure dew point warning" floating contact

- Electronic thermostat with floating output terminal

- mounted inside the unit, ready for operation

- Signal can be picked up on-site directly at the output

- Associated upper and lower switching thresholds configurable

Optional: Condensate drain, incl. floating contact

- Alternatively equipped with ECO-DRAIN 31 electronic condensate drain with floating alarm contact

- Signal can be picked up directly on the drain

- Air / air heat exchanger

- Air/refrigerant heat exchanger

- Condensate separators

- Condensate drains

- Refrigerant compressor

- Refrigerant condenser with fan (air-cooled)

- Filter / dryer

- Capillary tube (refrigerant evaporation and cooling)

- Compressed air inlet

- Compressed air outlet

- Hot gas bypass controller