Save costs with genuine parts

KAESER has developed a new maintenance strategy for mobile compressors. To learn more about this, we spoke with Kevin Rosenbusch from Global Service Support. As a dedicated service specialist, he ensures that the entire after-sales product line and all services for MOBILAIR compressors meet customer requirements.

Mr Rosenbusch, why is now the perfect time for a new MOBILAIR maintenance concept?

What has changed exactly, and more importantly, how do our customers benefit from these changes?

New insights gained from long-term field studies have shown us that we are able to adjust the maintenance intervals on some of our maintenance parts for portable compressors equipped with combustion engines and electric motors as follows:

MOBILAIR compressor maintenance intervals

| Old interval | New interval | |

| Compressor and engine air filter kit | 500 h / every year | 1,000 h / every 2 years |

| Compressor oil and oil filter kit | 1,000 h / every year | 1,000 h / every 2 years |

| Dirt trap and oil separator kit | 500 h / every year | 1,000 h / every 2 years |

| V-belt and engine coolant | 1,500 h / every year | 1,500 h / every 3 years |

| Hose lines | 3,000 h / every 6 years | No replacement required |

As you can see in the table, we have been able to extend the maintenance intervals – resulting in significant cost savings.

We often hear that it is considered “proper maintenance” only if genuine parts are used. Are there significant advantages to using genuine parts?

- Specific pressure and delivery volume

- Specific compressed air quality

- Energy and operating efficiency

- Ease of maintenance

- Frequency of maintenance intervals

- Compressor service life

Does extending these maintenance intervals mean that the performance of the compressor is compromised in any way?

No, not at all. Based on our long-term observations, we can assure our customers that these extended intervals have no negative impact on efficiency, performance, reliability or compressed air quality. Quite the opposite in fact, this new maintenance approach is about combining higher-quality genuine parts with added benefits.

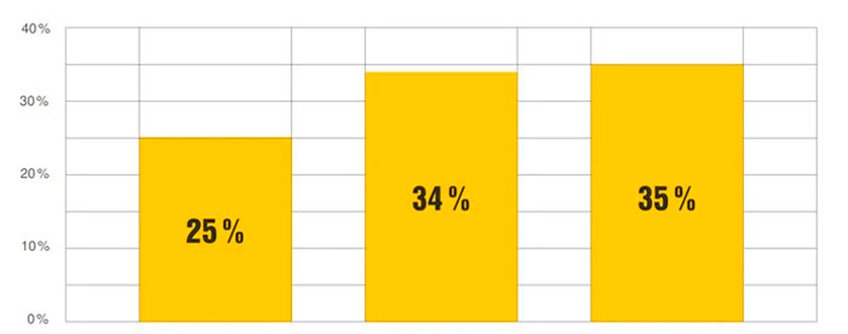

Average time saving

with our new maintenance strategy over a 6-year period

| Time saving 25% < 5 m³ /min | Time saving 34% 5 – 10 m³ /min | Time saving 35% > 10 m³ /min |

With these new service intervals, we can help our customers save up to 50% on maintenance material costs and up to 35% on labour costs over a six-year period. This has a significant impact on the total cost of ownership (TCO) calculation. Furthermore, our customers benefit from additional cost savings such as reduced disposal costs and a decreased CO2 footprint.