KAESER solutions for starting air

The combination of power, safety and reliability makes KAESER starting air compressors the ideal choice for a wide range of applications. Modular design enables quick and straightforward installation, saves space and assures maximum maintenance- friendliness. The compressors are available with different drive options and can be optimally adapted to specific applications using a variety of accessories. Air-cooled compressors require minimal maintenance, are exceptionally compact and achieve low airend discharge temperatures. Water-cooled reciprocating compressors can be optionally equipped to facilitate seawater cooling.

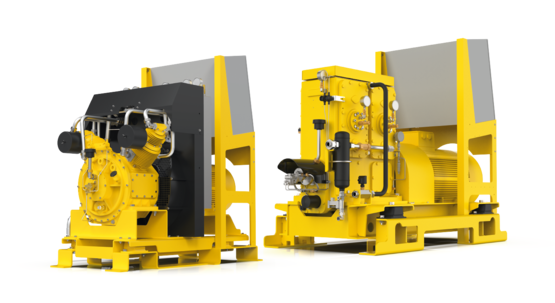

Air or water-cooled starting air compressors

Equipped with 1 to 3 cylinders depending on flow rate, starting air compressors compress atmospheric air in 2 or 3 stages to working pressures up to 40 bar. Due to the wide range of options available, air or water-cooled compressors can be used on various types of vessel – from yachts to cruise ships, right up to container ships and tankers. With low installation and maintenance costs, starting air compressors are therefore the ideal solution for high performance requirements.

Cooling for water-cooled compressors is possible via fresh water, as well as seawater, whilst simple handling and intelligent control ensure efficient operation at all times.

Your benefits

- Wide range of options

The compressors are available with different drive options and can be optimally adapted to specific applications using a variety of accessories. - International certified valves

Starting air receivers are equipped with matching valve heads in nominal sizes DN 38 (as per DIN 6276), as well as DN 50 and DN 80. The shut-off, safety and control fittings are arranged centrally on the valve head and are enclosed in a compact housing. - Modular design

Custom-made modules ensure very short assembly times. Fully assembled, piped and wired, the units are completely ready-to-run following minimal installation effort.

Compressed air receiver

Starting air receivers are used to store the compressed air required to start large diesel engines. The main areas of application are industrial power plants and ship propulsion systems. the receivers are supplied as standard in sizes from 30 to 2500 litres for a working pressure of 40 bar. Larger receivers and special versions with volumes up to approximately 25,000 litres, or with other operating specifications, are manufactured individually according to customer requirement.